Fabrication and Pressure Sensing Characterization of an Ultrathin Egg-Shaped Microbubble

Guanjun Wang,

Mengxing Huang,

Jinrong Liu,

Yuhang Li,

Shubin Zhang,

Xue-Fen Wan,

Muhammad Sohail Sardar,

Jianning Han,

Qingche Song and

Zhiguo Gui

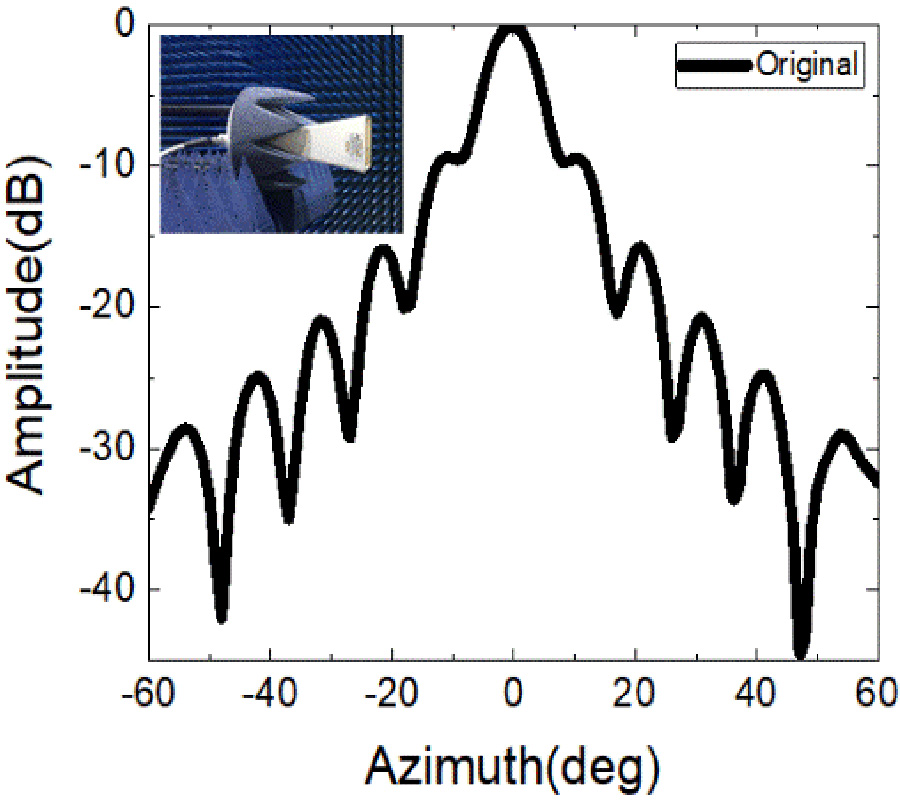

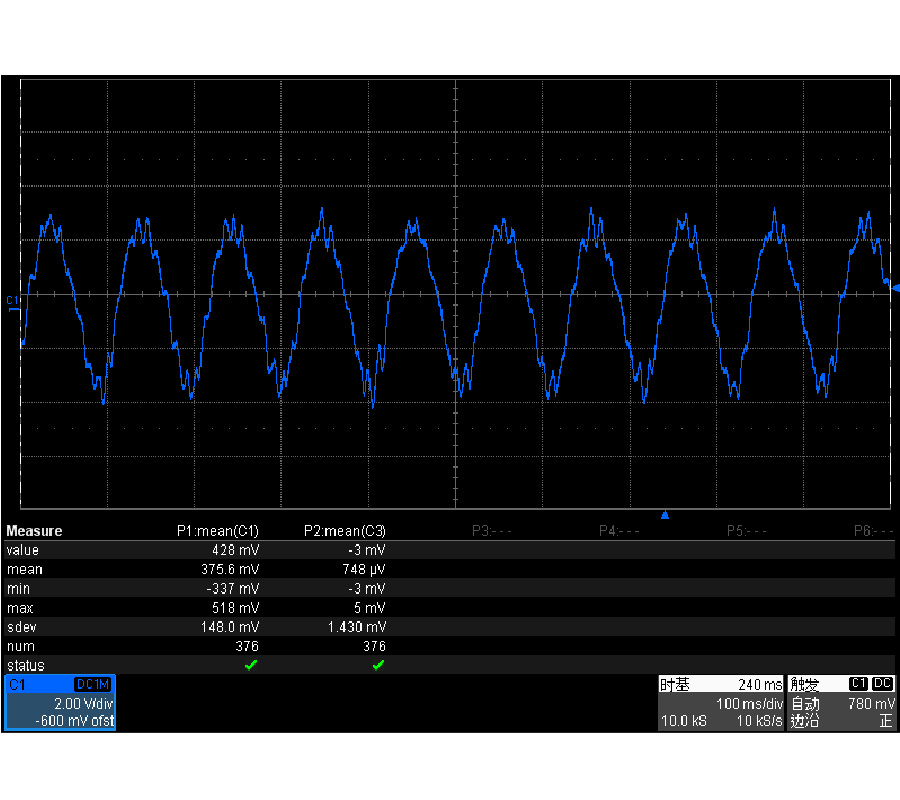

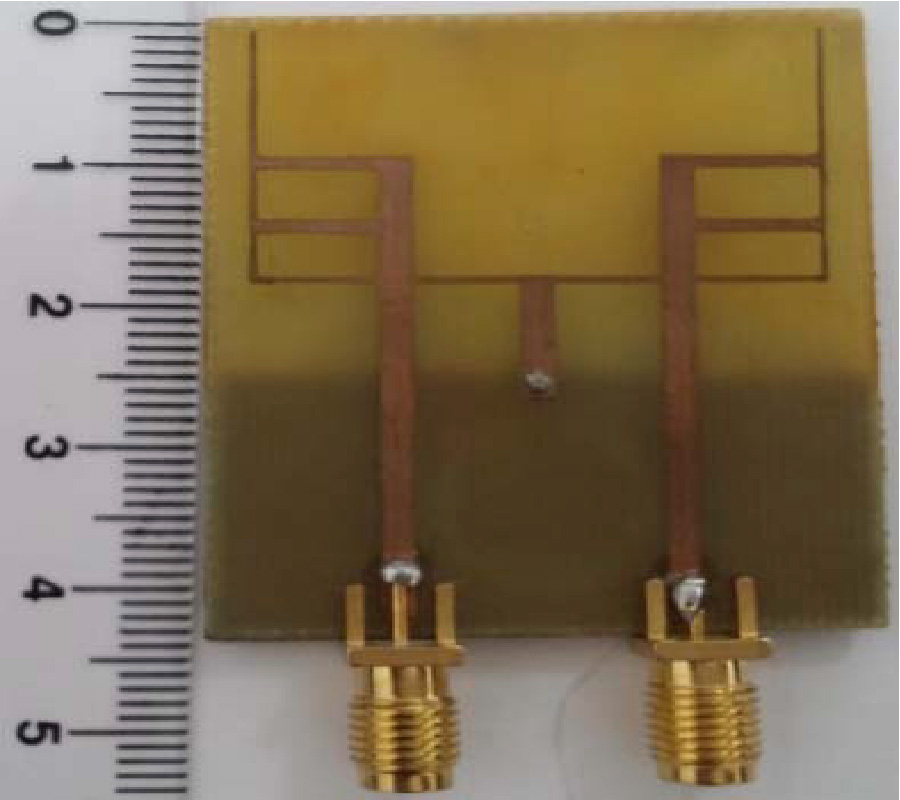

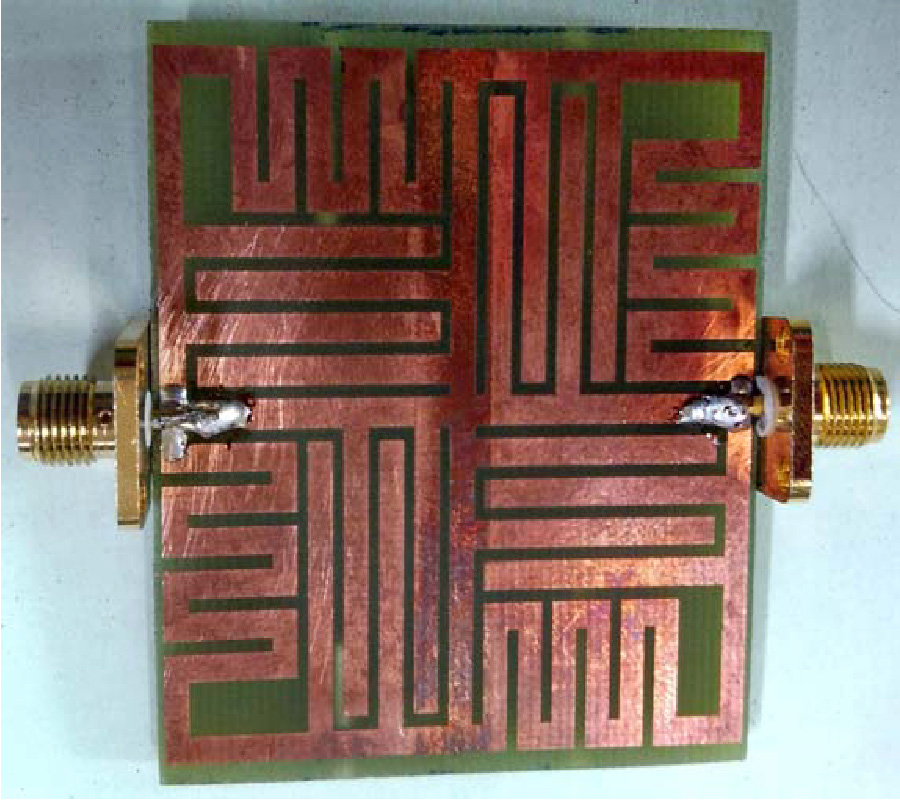

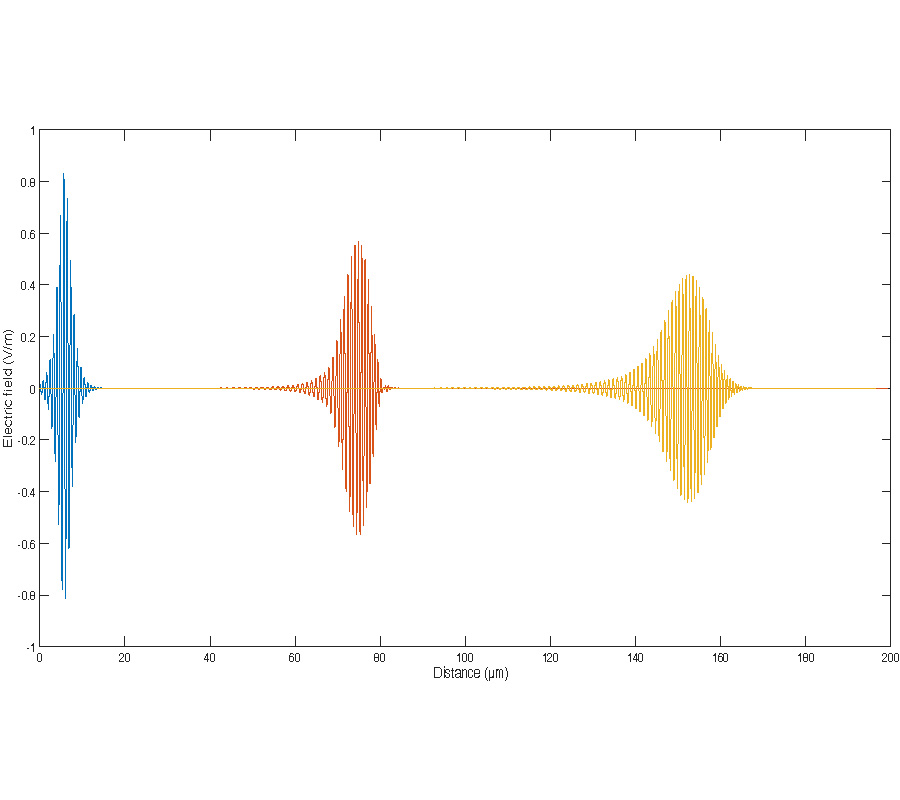

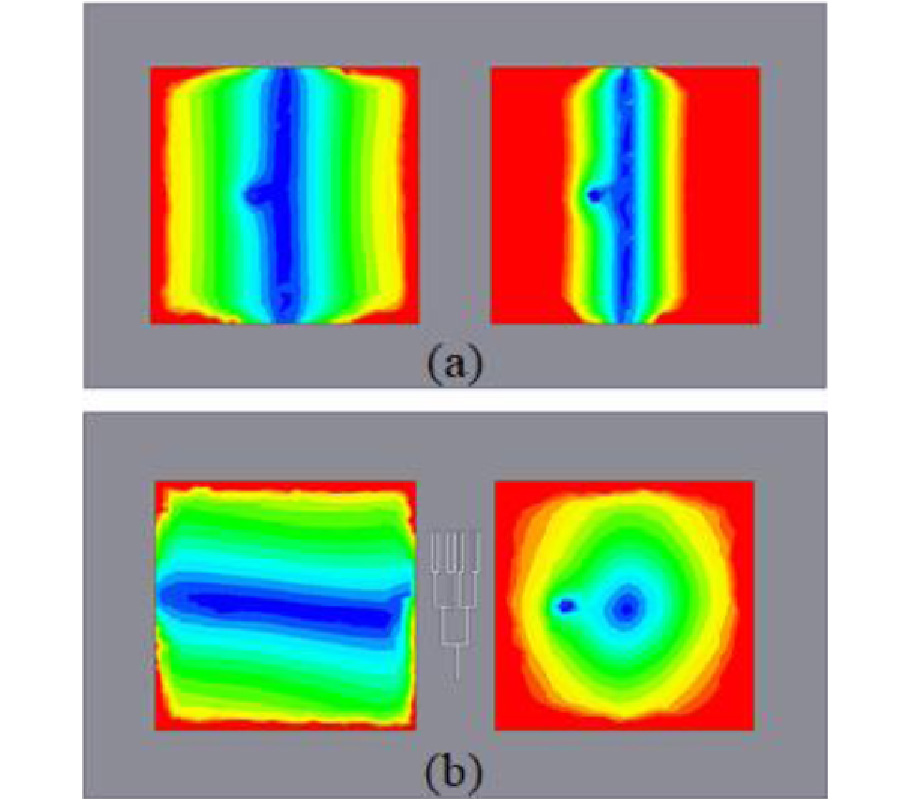

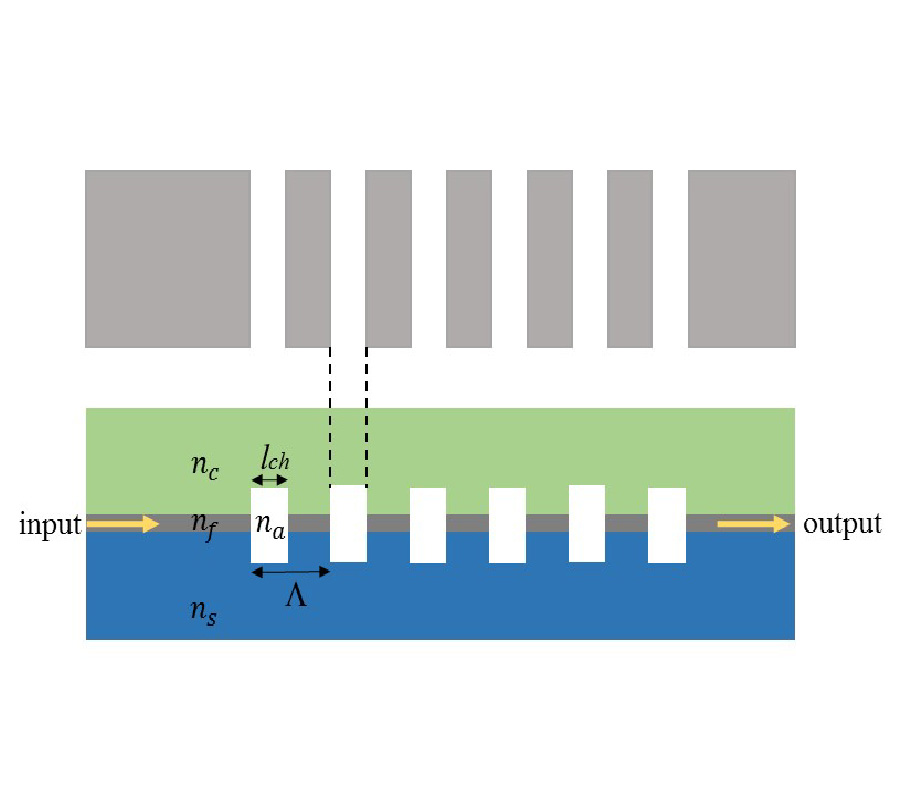

In this paper, an ultrathin egg-shaped microbubble was proposed and analyzed for pressure sensing firstly, which was fabricated by utilizing an improved pressure-assisted arc discharge technique. By tailoring the arc parameters and the position of glass tube during the fabrication process, the thinnest wall of the fabricated microbubble could reach 873 nm. Such an ultrathin film structure is very suitable for pressure sensing. Especially, as only a commercial fusion splitter and pressure pump were utilized to achieve such functions, the fabrication cost was very cheap. The fiber Fabry-Perot (FP) interference technique was used to analyze its pressure sensitivity by filling the inner wall of the microbubble with different air pressures. The experiment results depicted that the end face of microbubble expands with the increase of the filling pressure. The pressure sensitivity of such an egg-shaped microbubble could reach up to 14.3 pm/kPa in terms of interference spectrum shift, while the maximum cavity deformation sensitivity of the microbubble vs. pressure could reach up to 0.334 nm/kPa in terms of cavity length change. Besides, the maximum sensitivity vs. temperature was only 27.83 pm/˚C. Results of this study could be good reference for developing new pressure sensors with low cost, high sensitivity and good anti-temperature interference abilities.